In the age of computer engine management, people seem to have trouble operating the manual choke on their SU carb-equipped Bugeye (or similarly equipped classic car). So we made a detailed video that breaks down the components so choke operation will be come easy to master for all, for generations! Watch below and give us a call for your Bugeye parts needs!

Nick’s Tech Tips: Don’t let broken brakes leave you hosed!

Hydraulics are the number one fault area on British cars, primarily because moisture gets in the fluid and causes problems. The most common repair issue in the hydraulic system is leaking or seized wheel cylinders, master cylinders, and slave cylinders… but there is one issue that sometimes gets lost in the shuffle during maintenance proceedings… rubber hydraulic hoses.

This week, we had a Bugeye up on one of our lifts for a complaint of sticking rear brakes. The car would stop, but the rear brakes would stay applied even after the brake pedal returned. After a few minutes, the rear brakes would release and the cycle would repeat itself. This is a tell-tale sign that your brake hoses need to be replaced. In the below photo, you can see why:

Brake hoses are made of rubber. As with any rubber part exposed to the elements, brake hoses deteriorate over time; standard hydraulic fluid, which absorbs moisture from the atmosphere, doesn’t help matters, either. The “fun” part about brake hoses is that they are double-layer hoses, two layers of rubber bonded together. The most common failure point on hoses is not an external rupture and susequent leak; what usually happens is the two layers of rubber separate, the inner layer collapses on itself, and your brake hose turns into a one-way check valve. This allows brake pressure to travel to the brakes and applying them, but not allowing the fluid to travel away from the wheels to allow those brakes to retract. It will feel like your parking brake is stuck on, but in reality, your brake hose is holding the fluid hostage!

[Read more…] about Nick’s Tech Tips: Don’t let broken brakes leave you hosed!Is an EV classic car right for you?

This is a “charged” topic (pun intended). Like it or not, EVs are the next big thing in the automotive world. Perhaps your neighbor just got an EV, and maybe you’ll be getting one soon too. And EV media hype is likely to stay “amped up” for the foreseeable future, as more and more new EVs come on the market.

Maybe this is exactly why classic cars should stay gas-powered… to stay “classic.” And there is a large group of consumers who fully intend to keep their ICE-powered old car and the exhaust note that comes with every gas-powered vintage car. I own about nine gas burners in my little collection, and I’m with you!

But hear me out, because I believe we should welcome EV classic cars with open arms, also. Our company is still very committed to great gas-powered restorations, parts and modifications, and we expect that gas engines will occupy most of our energies for the foreseeable future. But we also believe that EVs are one of the best ways we can produce the most reliable classic cars on the road. The motors are bulletproof. There’s no transmission to jump out of gear or leak oil. No carburetor issues. And no clutch issues for clients with knee, hip or body challenges… one-pedal driving is easy on the body.

[Read more…] about Is an EV classic car right for you?Fresh Rubbers!

Before Spring driving season blooms, make sure to give your car a good visual inspection, with a particular focus on your rubber bits. (If you’re looking to get your car ready to drive this spring, and would rather have us run through it and tighten things up, give us a call and we will be happy to give your car the attention it needs… we pick up nationwide).

The examples below came to us from an armada of British cars here in our workshop for driving-season maintenance. For example, inner control arm bushings need to be fresh so that your suspension is good and tight. These were long past their expiration date. If you see cracked rubber flared out around your inner control arm mounts, it’s time to replace!

Here are some motor mounts we removed this week from a Morris Minor, also well past their useful life. Morris Minors and Bugeyes use the same engine mounts, so if yours look like this, make the change!

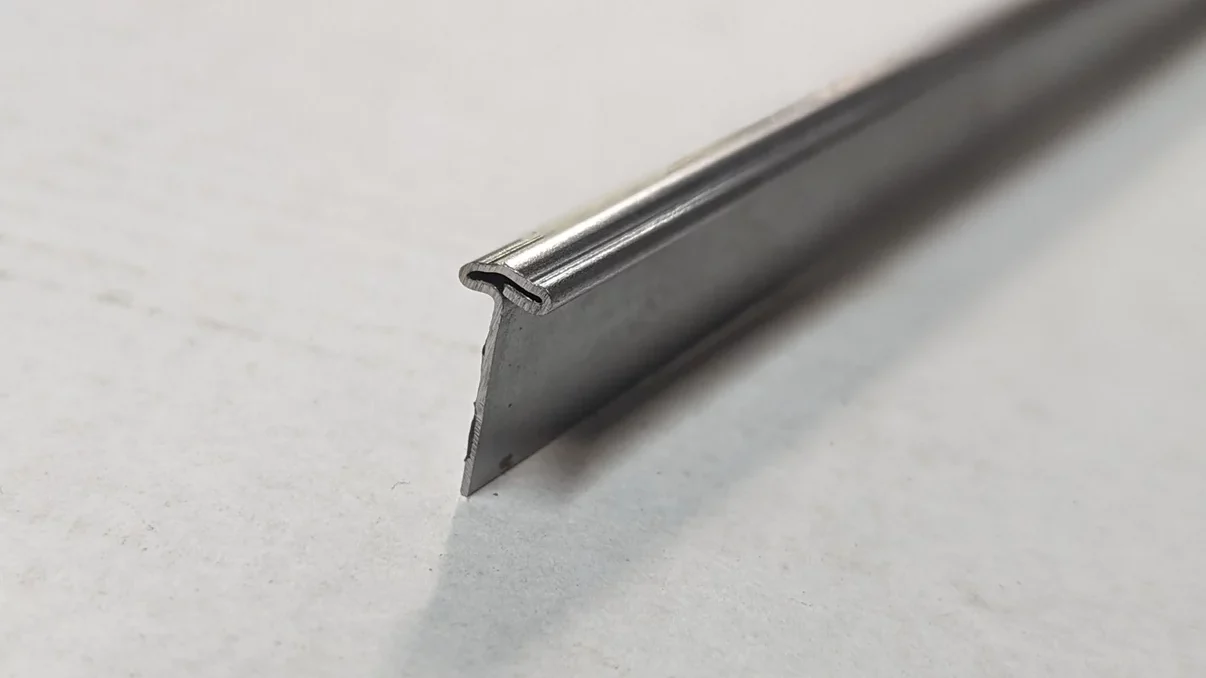

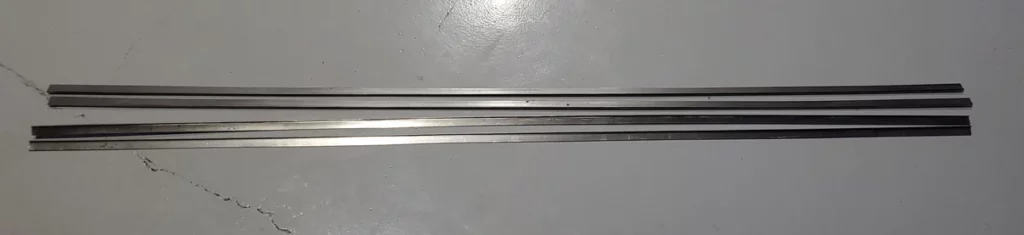

Bugeye fender-top beading properly configured and terminated

The beading on the tops of the Bugeye bodies are sometimes damaged or removed in restoration. Here’s a video about how to restore them to their original configuration. Make sure to get your beading cleaned-up and properly terminated before the paint goes on!

Beading came in a “T” section and plugged into the seams and was brazed in place in the factory that built the original bodies. Some restorers like to cut off the bottom leg of the “T” and attach the flat strip along the seam to recreate the original look. Once installed, make sure to avoid hitting the bead strip with a sander or grinder or you will ruin the original profile of the strip.

Should your beading be missing or damaged on your Bugeye, we offer a full body beading kit that provides enough beading material to do an entire Bugeye, with a little bit left over! Click on the photo below to get yours, or click here to view our full catalog! We can also provide cut sections in case you only need a small strip. Call or email for help!

One car, five different numbers!

Every week, we get a new question regarding the numbering system of these cars. It’s confusing. For example, the body panel stamping factory assigned a BAE number, which didn’t match the chassis number, or the engine number!

It helps to understand that each Bugeye was handled by several different factories all over England before it drove to the yard for shipment to the USA. The base chassis was stamped and welded at John Thompson Motor Pressings, and then the car was shipped to Pressed Steel, where the body panels were made and welded onto the tub.

From there it was on to the Morris factory for paint, and then one more leg of the journey brought the painted tubs to the Abingdon MG factory where the cars were assembled. Engines also were made off site, and they would ship-in from the Morris engine factory. So you had multiple players, and multiple numbers from multiple sources, and no unified numbering system.

In the video below, we dig into these various numbers to help you make sense of how all 50,000 or so Frogeyes came to life. And if you would like a heritage/birth certificate for your car, click here!